In Mould Labelling (IML)

Star Automation Europe has been manufacturing IML automation systems since 1995.

The long experience we have gained in this important field has driven us to develop more and more flexible and high-performing solutions.

IML applications, which are mainly used on food containers produced by 2, 4, 8 and 16 cavity moulds, are normally carried out by our S7 Flex side-entry robot. Star has also reached important results in other sectors where IML is required: paint containers are just one example that shows how a vertical entry robot, like the XW-VI or the ZXW-VI model, can be used depending on specific cycle requirements.

Here are two possible alternatives:

IML with side-entry robot

S7 Flex IML System:

This automation system features 7 servo driven axes for the whole management and handling of moulded products and labels. Thanks to their wide strokes, these applications can be installed on IMMs with clamping force ranging between 200 and 750 tons. All dimensions, times and programs can be stored, as all movements are performed by servomotors; this makes production changes considerably easier and ensures major quality and accuracy. A series of options completes this system and makes it ideal to be used in cleanrooms.

.jpg?1663335697)

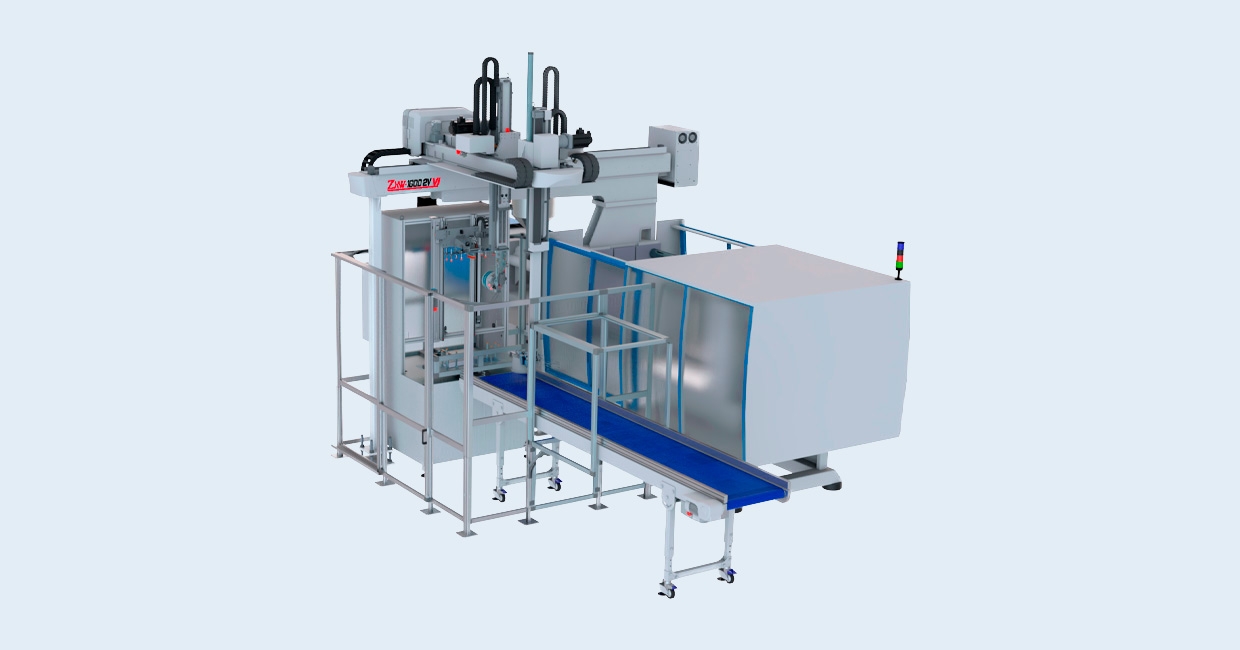

IML with top-entry robot

This is a really flexible solution for applications with cycle time >8 sec, used mainly for large size products. The open mould daylight is very little and standardised components are used as much as possible. A version with two vertical arms is also available. The set-up time for production change is very short, so production is optimised.