Automazioni industriali: la più innovativa tecnologia giapponese a servizio dell’Industria 4.0 europea.

La filosofia di Star è quella di creare sistemi industriali automatizzati con un posizionamento estremamente accurato che soddisfino le esigenze produttive dei clienti, disegnati per ottenere un tempo ciclo più ridotto possibile utilizzando robot standard.

Utilizziamo componenti adottati nella produzione su larga scala dal Gruppo Star: robot standard, un solo controllore capace di gestire l’intera automazione, componenti per mani di presa, tutto prodotto da noi.

Star Automation, nella sua produzione unisce la tecnologia giapponese alla fantasia e versatilità progettuale italiana. Questo mix di competenze ci permette di sviluppare automazioni flessibili nell’utilizzo e rispondenti alle più disparate esigenze del cliente, mantenendo costante l’alta qualità dei prodotti e la loro lunga vita lavorativa.

Un buon investimento oggi per un grande risparmio domani

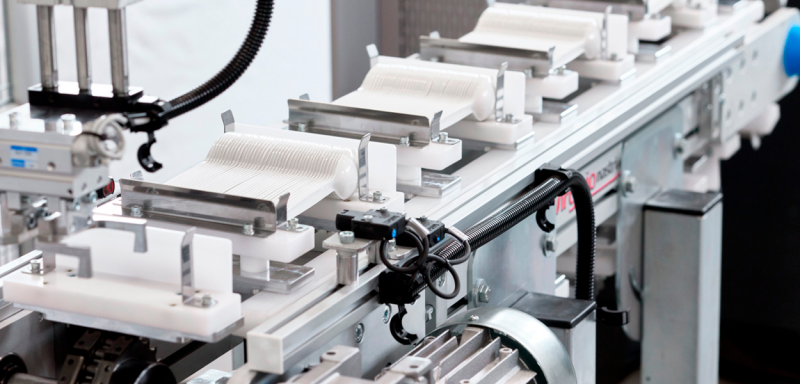

IML

Sistemi di automazione IML flessibili, con la massima efficienza in termini di prestazioni.

Automazioni per carico inserti

Automazioni per il carico di inserti studiate per garantire la massima produttività e precisione in fase di stampaggio.

Posateria

Sistemi di automazione chiavi in mano nel settore posateria.

Pallettizzazione

Robot pallettizzatori per la pallettizzazione in linea di prodotti imballati o meno.